During the operation of boiler systems, the formation of scale often causes serious problems. Scale not only reduces the operating efficiency of the boiler but also increases maintenance and repair costs. Therefore, the application of effective and optimal boiler scale treatment methods is necessary to maintain stable operation and high efficiency for the boiler system.

Causes of rust scale formation in boilers

When water is heated in a boiler, some of the water turns into steam. This steam is used for various purposes such as power generation, industry, etc. Along with water, impurities and minerals in the water also evaporate and adhere to the boiler walls. Over time, these substances accumulate and form scale. The scale in the boiler mainly consists of compounds such as CaCO3 (calcium carbonate), MgCO3 (magnesium carbonate), CaSO4 (calcium sulfate), etc. These compounds are in solid form, adhere to the boiler walls, and reduce heat transfer efficiency.

The harmful effects of boiler scale

- Equipment will be corroded and have a reduced service life.

- Pipes can be clogged, creating insulation, reducing thermal efficiency and damaging metals due to overheating of the boiler.

- Water contains many dissolved gases such as oxygen and CO2, causing oxidation, reducing durability and causing metal corrosion.

- Risk of equipment explosion during operation.

- Reduced heat exchange efficiency, capacity and productivity of equipment.

- Waste fuel and energy, causing economic losses.

- Pipes can be clogged or punctured, seriously affecting the production process and causing damage to the business.

The best method of boiler scale treatment

In solving the problem of scale in the boiler, there are some methods considered to be the most effective and optimal that you need to know

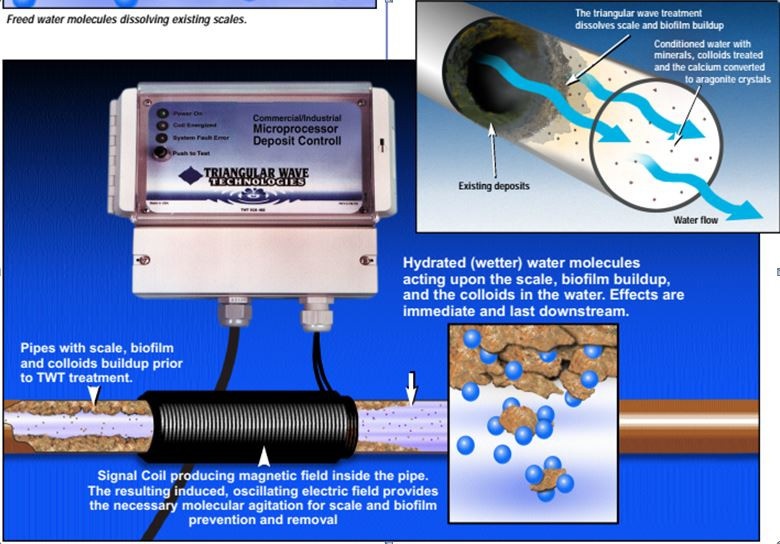

Boiler scale treatment with TWT electronic descaling device

This device operates based on the frequency conversion method, using a coil wrapped around a section of the water system pipe. When water passes through this section of the pipe, this method creates a special electromagnetic field, continuously changing the polarity, frequency and amplitude of the current transmitted to the coil. This environment stimulates water molecules and scale particles, leading to phenomena such as breaking down the structure of scale and moss, losing the ability to adhere to the surface of the device. At the same time, the device also helps to dissolve old scales on the surface, clean the water system and minimize problems related to scale in the boiler.

Boiler feed water treatment

Boiler water softeners reduce the hardness of water but do not completely remove organic and inorganic impurities and dissolved oxygen, leaving some hardness ions. These substances can cause scaling, corrosion and foaming, reducing the life, thermal efficiency and steam quality of the boiler. Changing the filter periodically from 3 to 6 months is also quite expensive.

Deionization (DI) and reverse osmosis (RO) systems treat water to near-purity. However, the initial investment cost is very high and does not bring good economic efficiency.

Use chemical detergent

The use of anti-scaling chemicals to clean the boiler periodically, usually every 6 months, is necessary to minimize the damage from accumulated scale. However, this method has many limitations such as being harmful to health and the environment, expensive and time-consuming. The off-boiler treatment system only partially minimizes the factors causing scale, not completely. Song Phung Water Equipment suggests the following two types of chemicals:

-

LTV110BA-AM: This chemical has anti-scale and anti-corrosion properties.

-

LTV110BA-CC: Contains phosphate radicals, which help to precipitate calcium in the form of mobile phosphate humus, preventing scale formation.

.

See more: Guide to choosing effective UV disinfection lamps for water and air

Measures to prevent scale formation in boiler systems

To ensure the performance of the boiler system and prevent the formation of scale, you can refer to and apply the following measures:

Blowdown control

Blowdown control helps to ensure that total dissolved solids (TDS) are at an acceptable level to prevent scale formation. If TDS is too high, scale will quickly form in the boiler. Blowdown must be carefully controlled to avoid wasting energy. For example, a 10% blowdown in a boiler with a pressure of 15kg/cm² can reduce energy efficiency by 3%.

The bottom discharge system usually has 2 forms:

- Instantaneous (intermittent) blowdown: Operates manually or automatically over time.

- Continuous blowdown: Adjusts blowdown rate and duration to suit boiler load.

Control fan and pump changes

Variable speed control of fans and pumps improves the efficiency and energy savings of boiler systems. Typically, combustion air is controlled by baffles in the furnace fan assembly.

However, the baffle often does not operate accurately, causing poor control at the beginning and end of the operation. When the steam load demand fluctuates, replacing the baffle with a frequency converter will help to adjust the fan and pump speed more accurately, increasing the operating efficiency and saving energy for the boiler.

Reduce boiler steam pressure

Reducing the steam pressure of a French boiler can save 1 to 2 percent of fuel consumption. Lower steam pressure not only reduces the saturated steam temperature, but also reduces heat loss throughout the system of piping, valves, and connections.

However, there are some disadvantages to reducing steam pressure that should be noted. As steam pressure drops, the boiling process in the boiler becomes more violent, causing water to be drawn into the system. This poor quality steam can damage and corrode valves, fittings, and piping, as well as overload steam traps.

In addition, because low pressure steam has a low density, the steam supply rate needs to be increased to meet the heat demand. Increased steam supply rate will increase friction loss and lead to a decrease in pressure in the steam supply system, causing a shortage of steam supply.

Boiler load control

The boiler operates most efficiently when its load reaches approximately 70% of the maximum design load (100%). When operating at this load, the boiler consumes energy more efficiently and optimizes the thermodynamic factors during operation.

If the boiler operates below this load, its efficiency will decrease because it will not be able to make full use of the supplied energy and the temperature and pressure control elements will not operate at their optimum state.

Plan to use the boiler properly

As we have provided above, the boiler operates most efficiently at a load level of 65% to 85% of its design capacity. Operating at this load level allows the boiler to convert energy more efficiently, reduce heat loss, and maintain the thermodynamic factors in an optimal state. If the boiler is operated at a lower load level, the boiler efficiency will decrease because the energy supplied by the boiler is not fully utilized and the equipment will not operate in the best condition. This leads to increased fuel costs, maintenance, and reduced equipment life.

Thus, applying measures to treat and prevent scale in the boiler system not only helps increase operating efficiency but also prolongs the life and reduces maintenance costs. Through this article, we hope you have an overview and better understand the most effective methods to treat scale problems in the boiler. At the same time, you can visit thietbinganhnuoc.com of Song Phung to ensure that your boiler system always operates stably and efficiently.

Reference: Pool filter sand replacement service