The best filtration solution is to achieve good filtration efficiency at the lowest cost. We choose the high-flow fine filter element to filter liquids because it has a high flow rate, large dirt holding capacity, is easy to replace and takes up little space. Let’s take a closer look at high-flow fine filter cartridges.

1. What is a high flow fine filter element?

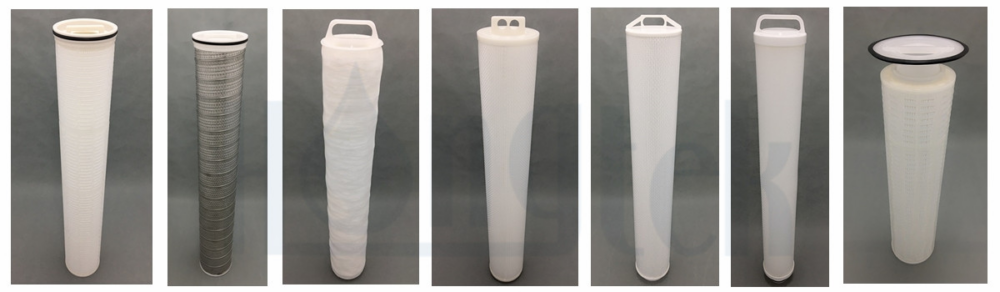

The high-flow fine filter element uses a deep fine polypropylene or glass fiber membrane as the filter material, has a large diameter of 6 inches/152mm, has no center bar, is one-way open, and is specially designed to flow liquid from the inside. out, ensuring all pollution particles are blocked inside the filter core. The super large flow rate design greatly reduces the use of filter elements and filter cores in the same flow rate application, greatly saving equipment investment costs and labor costs.

2. Working principle of high flow fine filter core

The high-flow fine filter element is designed with a large diameter for efficient filtration and has a high-strength support frame both inside and outside. It is made of multi-layer synthetic progressive filter material and is fusion welded integrated with the outer sealing ring. Designed with a single flow rate of 50-90m3/H, the high-flow fine filter cartridge is suitable for fields such as large-scale reverse osmosis pre-filtration. The new patented folding style of this high-flow fine filter element combined with a large 6/152mm diameter design reduces the number of filters and filter housing size requirements. At the same time, more filter media can be provided to meet other application requirements.

Working principle of high flow fine filter core

3. Advantages of high flow fine filter core

(1) Higher flow rate

Due to the large outer diameter of the high-flow fine filter element, it has a larger filtration surface area. Under the same operating conditions, the volume of liquid passing through a high-flow fine filter element will be greater than the volume of liquid passing through a depth filter element with an outer diameter of 2.5 inches.

(2) Takes up less space

When the water demand of the system is the same, the number of high-flow fine filter elements of the same length will be less, so the outer diameter of the high-flow fine filter element housing is also relatively small, thus reducing the capacity. system volume.

(3) Lower maintenance costs

Replacing the high-flow fine filter element is more convenient, helping to reduce labor costs. Because fewer high-flow filter cartridges are used in a system with the same type of water demand; Processing costs for high-flow fine filter cartridges will be lower than for waste disposal.

(4) Greater dirt holding capacity

Due to the large filtration surface area, the high-flow fine filter cartridge may contain more contaminants (colloids, particles, etc.) during the liquid filtration process.

(5) Higher production efficiency

If there is no backup filter system, it is necessary to first stop the machine and then replace the filter elements. Because the high-flow fine filter core replacement time is short, downtime is shortened, production time is extended, and production efficiency is improved.

4. Applications of high flow fine filter cores

• RO pre-filtration, sea water desalination pre-treatment

• Filter bottled water, high fructose content, cooking oil, beverage

• Solvent filtration and water filtration on the market

• Paint and coatings filtration, petrochemicals, oil refineries

• Microelectronic filtration

5. Instructions for replacing the high-flow fine filter element

Through many years of experience in the industry, to help users solve problems encountered when installing and replacing filter cartridges, we have summarized the following key steps to replace high-flow filter cartridges:

(1) First of all, we must check whether the technical parameters (length, outer diameter, precision, filter media, etc.) and quality of the high-flow filter meet the standards of use. and prepare the disassembly tool to replace the filter cartridge;

(2) Make sure the system is turned off and the high-flow filter housing inlet/outlet valves are closed;

(3) Slowly open the vent valve above the high-flow filter housing to relieve pressure;

(4) Slowly open the drain valve of the high-flow filter housing to drain the liquid in the housing until the liquid no longer flows out;

(5) Open the cover above the housing and take out the used high-flow filter in the housing;

(6) Thoroughly wash any remaining dirt on the surface and inside of the high-flow filter housing;

(7) Open the packaging bag of the high-flow fine filter cartridge and wet the O-ring on the end cover of the filter element with lubricant or water to prevent the O-ring from falling off due to friction when installing the filter cartridge;

(8) Manually insert the high-flow fine filter element vertically into the socket at the bottom of the housing, then install and fix the pressure plate of the housing, finally cover and lock the housing cover;

(9) Close the drain valve, then slightly open the water supply valve to let the liquid enter the high-flow filter housing, until the liquid overflows from the vent valve at the top of the housing, then close the vent valve;

(10) Slowly open the water discharge valve of the housing until it is completely open, then slowly adjust the water inlet valve until the pressure difference between the upstream and downstream of the high-flow filter housing reaches the differential value. initial pressure difference

See more: Do refrigerator filters really work?

To learn more about other powerful and unique water filtration systems distributed by Song Phung, order online at the website https://thietbinganhnuoc.com/san-pham or call us on our hotline 0913.90.72.74 – 0984.620.494 for detailed advice.

Follow Fanpage: https://www.facebook.com/SongPhungthietbinganhnuoc/ to be updated with new products.